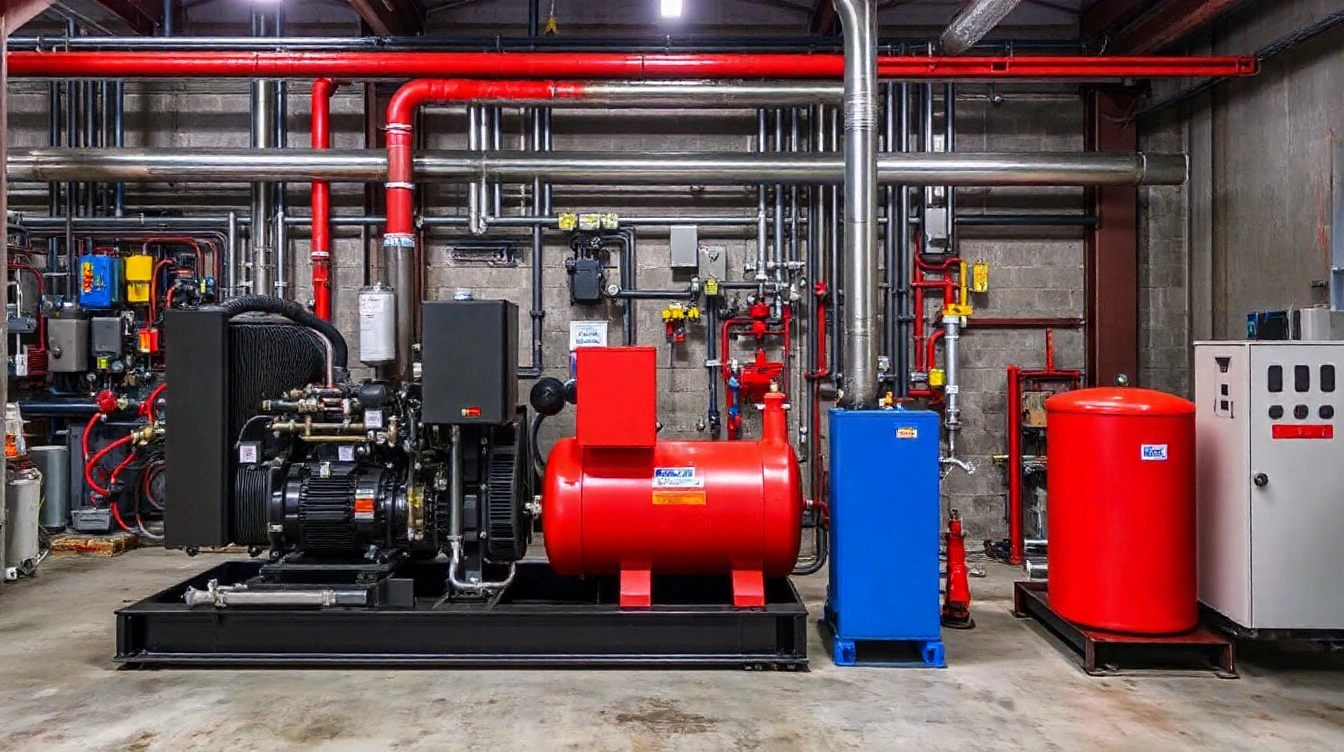

Setting up an industrial air compressor demands careful planning and precise execution to ensure peak performance and longevity. Understanding the right selection criteria, site requirements, and safety protocols lays the foundation for a successful installation. This guide breaks down essential steps and insider tips to help streamline your setup process, avoid common pitfalls, and optimize operational efficiency from day one. Equip yourself with practical knowledge that turns complex installation into a manageable, efficient task.

Step-by-step procedures for industrial air compressor setup

Mastering the industrial air compressor setup requires thorough planning and precise execution.

Have you seen this : Unlocking brand potential with expert event production services

The first critical phase in any industrial air compressor setup is the initial assessment and planning. This involves evaluating the site to determine the optimal location for the compressor, considering factors such as ventilation, accessibility, and proximity to power sources. Proper planning ensures the installation aligns with operational needs and safety standards.

Next, assembling the required tools, materials, and equipment is essential to avoid delays during the installation process. Common tools include wrenches, screwdrivers, pipe cutters, and measuring devices. Materials such as appropriate piping, fittings, and mounting brackets must also be on hand. Preparing these components before installation begins streamlines the workflow and promotes safety.

Also read : Expert removal company in glasgow for smooth relocations

Following preparation, the sequential steps for installing air compressors efficiently include securing the compressor base, connecting air lines, and establishing electrical connections according to manufacturer specifications. Each step should be conducted methodically to prevent errors. For example, proper torque settings on bolts and correct alignment of pipes are crucial to prevent leaks and maintain system integrity.

By adhering to this comprehensive installation guide, technicians can ensure a reliable, safe, and efficient industrial air compressor setup. For very specific or complex setups, consulting expert resources such as an industrial air compressor installation guide can provide additional benefits and reduce the risk of costly mistakes.

Key considerations for selecting equipment

When choosing industrial air compressors, understanding the compressor types and their specific benefits is essential. The main types include rotary screw, reciprocating, and centrifugal compressors, each designed to suit different application needs. For instance, rotary screw compressors are ideal for continuous operation and offer higher energy efficiency, while reciprocating compressors may be better for intermittent use with lower capital costs. Selecting the right compressor type prevents overpaying for unnecessary features and ensures operational reliability.

Capacity evaluation is crucial. You should match compressor capacity to actual air demand, measured in cubic feet per minute (CFM) and pressure requirements in pounds per square inch (PSI). Oversized compressors lead to wasted energy and expense, whereas undersized units may cause production delays due to insufficient air supply. Equipment selection tips emphasize consulting facility-specific usage patterns and future growth expectations to optimize these parameters.

Energy efficiency significantly affects operational cost. Factors like variable speed drives (VSD), proper motor sizing, and effective cooling can drastically reduce energy consumption. Although initial investments might be higher, energy-efficient compressors lower total lifecycle expenses and environmental impact. Moreover, tailored features such as integrated dryers or filters should correspond to your facility’s air quality needs to avoid additional post-installation equipment.

In summary, choosing industrial air compressors demands careful alignment of compressor types, capacity specifications, and efficiency features with facility requirements. These considerations not only ensure seamless operation but also enhance long-term economic and environmental sustainability.

Preparing the installation site for optimal performance

Site preparation is crucial for ensuring that an industrial air compressor operates efficiently and safely. Understanding the necessary installation conditions and compressor room requirements will prevent operational issues and extend the equipment’s lifespan.

First, the site location must be chosen with safety and accessibility in mind. The installation area should be easy to access for maintenance personnel and allow for smooth transport of parts. Additionally, it should be free from risks such as flooding or extreme temperature fluctuations, which can compromise compressor performance.

Environmental and structural prerequisites play a significant role in successful site preparation. The room housing the compressor needs to maintain clean, dust-free air to avoid contamination of the machinery. Structural integrity is essential, as the flooring must support the compressor’s weight without settling or vibration that could damage components.

Recommendations for the installation site focus on specific factors:

- Flooring: A rigid, level surface is necessary to stabilize the compressor and minimize vibration. Concrete floors are preferred over wood or tile.

- Ventilation: Proper airflow ensures heat generated by the compressor dissipates, preventing overheating. Installing ventilation systems or incorporating natural airflow paths satisfies this need.

- Power supply: The electrical infrastructure must supply stable voltage and adequate power capacity, matching the compressor’s requirements to avoid outages or electrical hazards.

Ensuring these installation conditions and compressor room requirements are met will maximize the efficiency of the equipment and reduce long-term maintenance costs. For detailed guidance on setting up an appropriate environment, especially regarding power and safety considerations, consulting resources on industrial air compressor installation is highly advisable.

Installation checklists and best practices

Your guide to seamless compressor setup

An effective installation checklist is essential to ensure every stage of the industrial air compressor installation follows a precise, compliant, and efficient setup workflow. Before beginning, a thorough pre-installation checklist guarantees that site conditions, power supply, foundation requirements, and safety standards meet project specifications, thus preventing costly delays and errors.

One critical aspect is properly mounting and anchoring the compressor. Correctly securing the unit prevents excessive vibration, noise, and premature wear. This step in the compressor installation steps requires using appropriate anchors and verifying that the compressor is level. Misalignment at this stage can escalate into operational challenges later.

Additionally, seamless integration of air lines, filters, and dryers must follow industry best practices. Air lines should be routed to minimize pressure drops and avoid moisture buildup. Filters and dryers are then connected to maintain air quality and prevent damage to pneumatic systems. Proper placement and secure connection of these components are vital in the setup workflow for optimizing performance and durability.

Following a detailed installation checklist streamlines the process while maintaining compliance with technical standards. For those seeking guidance on specific measures or expert recommendations, consulting resources on industrial air compressor installation can enhance understanding and confidence in managing each installation phase.

Critical safety measures during installation

Ensuring safe and secure compressor setup

When undertaking an industrial air compressor installation, adhering to strict safety protocols is essential to prevent accidents and equipment damage. One of the primary concerns is compressor installation hazards, which include risks such as high-pressure air leaks, electrical hazards, and heavy machinery handling. Identifying these risks early in the process allows for targeted control measures, minimizing potential dangers on-site.

Personal protective equipment (PPE) plays a crucial role in protecting technicians and installers. Appropriate PPE may include gloves resistant to cuts and punctures, safety goggles, hearing protection, and steel-toed boots. Additionally, following safe handling procedures for lifting and positioning heavy compressor components significantly reduces the chance of injury. Proper training ensures that personnel are aware of the risks and the correct ways to mitigate them.

Compliance with industrial safety standards and regulations, such as OSHA guidelines, is non-negotiable. These standards provide clear requirements for installation practices, electrical setups, and environmental considerations. Meeting these regulations not only safeguards worker health but also ensures the operational integrity of the compressor system after installation.

Optimizing air compressor performance and efficiency

Enhancing performance optimization in air compressors begins with addressing energy consumption proactively. Implementing energy-efficient compressors is essential for minimizing operational costs and environmental impact. One effective method is reducing energy usage by identifying and repairing leakage points within the system. Leaks lead to wasted compressed air, which significantly diminishes overall system efficiency and drives up energy bills.

Monitoring system pressures regularly ensures the compressor operates within its ideal range; too high pressure results in unnecessary energy use, while too low pressure can impair equipment functionality. Adjusting compressor controls to optimize load/unload cycles further boosts efficiency. This fine-tuning ensures the compressor runs only when necessary, reducing wear and saving electricity.

For businesses looking to advance their setup, understanding these principles alongside careful industrial air compressor installation can provide a strong foundation for sustained efficiency. Proper installation aligns the components correctly, making ongoing performance optimization easier and more effective.

Common setup pitfalls and how to avoid them

Precision in industrial air compressor installation is critical.

One of the most frequent compressor setup mistakes is overlooking proper alignment and anchoring during installation. Misalignment can cause excessive vibration, leading to premature wear and costly repairs. Ensuring the compressor is firmly anchored to a stable surface minimizes vibration and maintains efficient operation. This step is not merely about physical stability; it protects the entire system against early mechanical failures.

Another common issue is inadequate air filtration or moisture management. Without effective filtration, contaminants can enter the compressor, causing damage and reducing lifespan. Similarly, moisture buildup is a silent threat that can corrode internal components and degrade compressed air quality. To avoid installation errors related to air quality, always incorporate suitable filtration devices and moisture separators right from the start. This guarantees cleaner, drier air and fewer maintenance headaches.

Incorrect pressure settings also rank high among troubleshooting concerns. Setting pressure too high may waste energy and stress the system, while too low pressure compromises performance and safety. Precise calibration based on operational requirements ensures the compressor runs efficiently and safely. Monitoring gauges during setup helps quickly identify improper settings before they cause issues.

In summary, avoiding these key installation errors improper alignment and anchoring, insufficient filtration or moisture control, and inaccurate pressure settings — greatly enhances the reliability and longevity of any industrial air compressor system. For those seeking expert guidance, resources on industrial air compressor installation offer detailed insights into best practices to prevent these pitfalls.

Routine maintenance guidelines

Maintaining an industrial air compressor is essential to ensure its reliability and longevity. One of the first steps is establishing a clear compressor maintenance schedule immediately after installation. Setting regular service intervals helps prevent unexpected breakdowns and keeps the system running efficiently.

Key maintenance tasks include thorough inspection of critical components, regular lubrication of moving parts, and timely filter changes. Failure to perform these actions can lead to accumulated wear and reduced performance. For example, filters clogged with dust or debris restrict airflow, forcing the compressor to work harder and consume more energy.

Recognizing early signs of wear or system inefficiency is vital. These can manifest as unusual noises, excessive vibration, or a drop in pressure output. Addressing these symptoms early prevents costly repairs and prolonged downtime.

For a practical resource, consulting expert advice on industrial air compressor installation can guide the integration of maintenance planning into your operational routine. Regular preventative care not only optimizes performance but also extends the compressor’s service life significantly.

Basic troubleshooting during and after installation

Small issues can arise, but timely action helps maintain smooth operation.

Troubleshooting compressors efficiently starts with recognizing common installation errors. These often include incorrect alignment, improper mounting, or insufficient lubrication. Identifying such faults early prevents damage and performance loss. For example, a compressor running unusually hot or producing erratic noises typically signals setup issues related to ventilation or component fitting.

Diagnosing setup issues also involves checking electrical connections and verifying pressure settings match manufacturer specifications. If you notice reduced airflow or inconsistent pressure, these symptoms pinpoint potential misconfigurations or leaks in the system. Simple corrective actions like tightening fittings, resetting control parameters, or cleaning filters can resolve many immediate problems without extensive downtime.

However, if troubleshooting compressors reveals persistent or complex issues such as failure to reach target pressure, unusual vibrations, or frequent circuit breaker trips—it is advisable to seek professional installation support. Experts can perform in-depth diagnostics, using specialized tools to detect hidden faults that are not obvious during routine checks.

For those involved in industrial air compressor installation, understanding these troubleshooting basics is critical. It ensures any teething troubles are addressed promptly, safeguarding equipment longevity and operational safety. When in doubt, professional support serves as a reliable resource to optimize compressor function and avoid costly repairs later.

Additional resources and downloadable tools

For anyone aiming to master compressor setup resources, access to clear and systematic materials is essential. Visual aids like installation diagrams and workflow charts play a pivotal role by illustrating complex processes step-by-step. These diagrams simplify understanding the correct sequence and configuration needed during the setup, reducing errors and ensuring efficiency.

To complement visual guides, downloadable checklists and quick reference guides offer practical aid during each phase of the project. These tools help verify that critical steps in the compressor setup are not overlooked. For instance, a checklist might include verifying input power connections, pressure settings, and safety valve calibrations helping to maintain compliance and operational safety.

In terms of ongoing support, many professionals seek platform-based technical guides and forums that offer in-depth knowledge and troubleshooting tips. Resources often provide educational content focusing on maintenance schedules, performance optimization, and troubleshooting common issues in compressor installations. One authoritative resource for those handling complex machinery is specialized content related to industrial air compressor installation, which can be found at expert sites covering best practices and detailed setup procedures.

By combining visual aids, comprehensive checklists, and expert technical guides, users benefit from a well-rounded toolkit. This integration ensures that both novices and experienced technicians can approach compressor installation with confidence and precision.